22 mins read

Success Story: How RIB 4.0 Powers The High-speed Of The High-speed Railway Projects In North China

The Company

China Railway Group Limited (also known as CREC) is a world-leading construction conglomerate. As one of the world’s largest construction and engineering contractors, CREC takes a leading position in infrastructure construction, industrial equipment manufacturing, scientific research and consulting, real estate development, resources development, financial trust, trade, and other fields.

The Company ranked 50th among the “Fortune Global 500” in 2021, the 16th successive year being listed, while at home it ranked 5th among the Top 500 Chinese Enterprises. Over the decades, the Company has built more than 2/3 of China’s national railway network, 90% of China’s electrified railways, 1/8 of the national expressways and 3/5 of urban rail transit systems.

The Challenge

China’s railway construction had problems commonly seen in the construction industry: low-level adoption of information technology, extensive management, low efficiency, and low qualification of construction personnel.

Other than those challenges, railway engineering has its own set of unique characteristics: numerous complicated fields involved in a project, coordination of complex information amongst teams, tight construction periods, along with the management facing the ongoing challenges of scheduling, safety, and quality.

Thus, the railway industry had been exploring ways that can help to improve railway construction by reducing costs, shortening construction periods, improving efficiency, and achieving lean and sustainable construction and development.

As a subsidiary of China Railway Group, China Railway Engineering Consulting Group (CEC) developed its own strategies for enterprise digital transformation – bridging virtual and physical technology and management systems through the increasingly mature BIM technology, along with driving platform thinking with connected data, to create an efficient industry ecology that better serves partners, making the concept of “no difficult engineering projects” become a reality, and laying the foundations for smart design, construction, operation, and maintenance.

“For an enterprise with the mindset of managing within a data-driven platform, big data becomes key asset, and provides the basis for a new type of enterprise productivity and forms the core of digital transformation. A collaborative platform dedicated to the success of all stakeholders is the core competitiveness of all new enterprises and mature businesses wishing to compete in the digital era. ”

— Wang Xiaogang

General Manager, Jinan Informationization Center

China Railway Engineering Design & Consulting Group., Ltd

The Solution: RIB 4.0 platform

China Railway Engineering Consulting (CEC) had been looking for partners with a similar mindset. After in-depth research, China Railway believes that RIB Software, a global leader in digital solutions for the construction industry that promotes new thinking, new working methods and new technology, as well as 5D BIM solutions, is aligned with their digital strategy.

They joined the RIB 4.0 Community in 2015 and started their long-term partnership with RIB Software, paving the way for even greater engineering feats and accomplishments. REC started managing their project on the RIB 4.0 5D platform from 2016. In 2017, they started to upgrade to the RIB 4.0 platform. With this platform, REC achieved industry-level application, and by realizing the implementation of one integrated platform connecting and managing multi-processes and the collaboration among different project stakeholders, have created a mindset within the company that ‘no project is too difficult’.

Successful Projects with RIB 4.0

The initial RIB 4.0 projects have been 10 high-speed railway stations along the Jinan-Qingdao high-speed railway. CEC used the RIB 4.0 platform to simultaneously manage these projects. The implementation feedback from all aspects is positive and this has laid a foundation for the implementation of RIB 4.0 on more subsequent projects. During the tendering phase, the company saved about 10 million RMB from being able to quickly locate over 100 defects in the bill of quantities using BIM 5D.

Jinan East Railway Station Qingdao Railway Station

Zibo North Railway Station Weifang Railway Station

Qingdao Metro LuNan High-Speed Rail

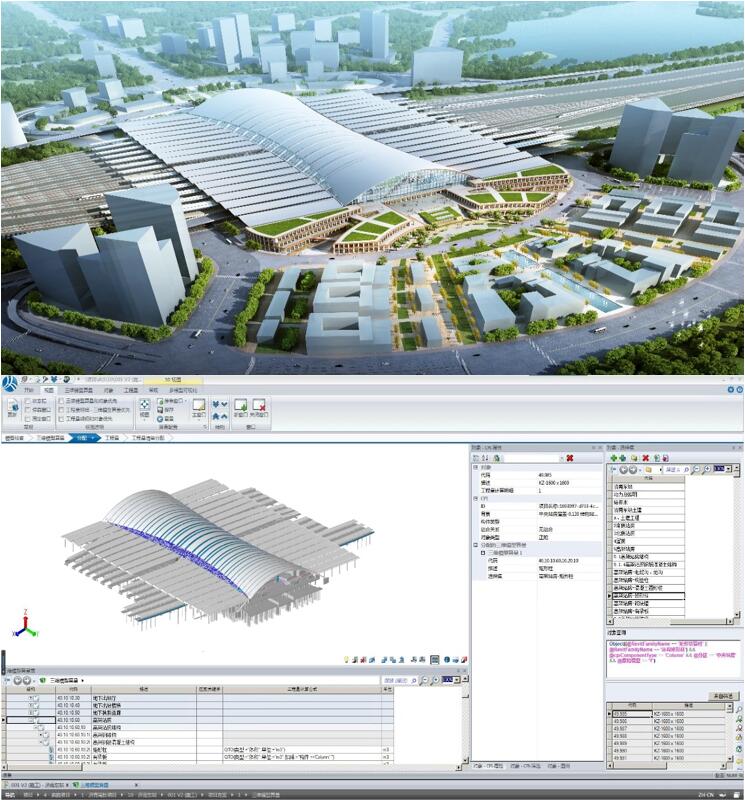

RIB 4.0 Goes High-Speed with Jinan East Railway Station

The Jinan-Qingdao high-speed railway is a high-speed railway link between Qingdao and Jinan, the two main cities of Shandong Province, China. Tracklaying started in 2017 and the whole line (307.9 kilometers) was opened on 26 December 2018, shortening the traveling time between Jinan and Qingdao to just 1 hour.

Jinan East Railway Station is a high-speed railway station in Jinan, the capital city of Shandong Province. It is the third major station in Jinan, following the central Jinan railway station and Jinan West Railway Station. Jinan East is located on the east-west Jinan-Qingdao high-speed railway, with 13 platforms and a floor area of 59,740 square meters.

Jinan East Railway Station

1. BIM modeling

With the smart plugin RIB 4.0 3D linking Revit and RIB 4.0, CEC was able to effortlessly synchronize their BIM models between Revit and iTWO to eliminate back and forth importing and exporting work. Once models are imported to RIB 4.0, the China Railway team can review and integrate multi-major models.

2. Quantity takeoff and estimation

The size and complexity of the Jinan East project demands different teams working on different fields (i.e. earthwork, mechanical, engineering, and plumbing) of the project quantity takeoff and estimation, then combine them into one Bill of Quantities. With RIB 4.0 master database, the teams were able to realize “quantity takeoff with one click”, saving precious time by simplifying the process.

3. Scheduling & 5D BIM virtual simulation

Project schedules are connected to BIM models in RIB 4.0. CEC was able to run 5D BIM virtual simulation: 3D models + time + cost information. This integrated scheduling enables better planning for uncertainties and risks, allowing visibility of the impact of any schedule changes to help teams allocate resources more effectively and efficiently. For instance, based on 5D BIM virtual simulation, the CEC team found that their previous steel roofing plan would take 5 months to complete, which would inevitably lead to project delay. With this finding, they rearranged the steel roofing installation plan, which saved them one month of project schedule.

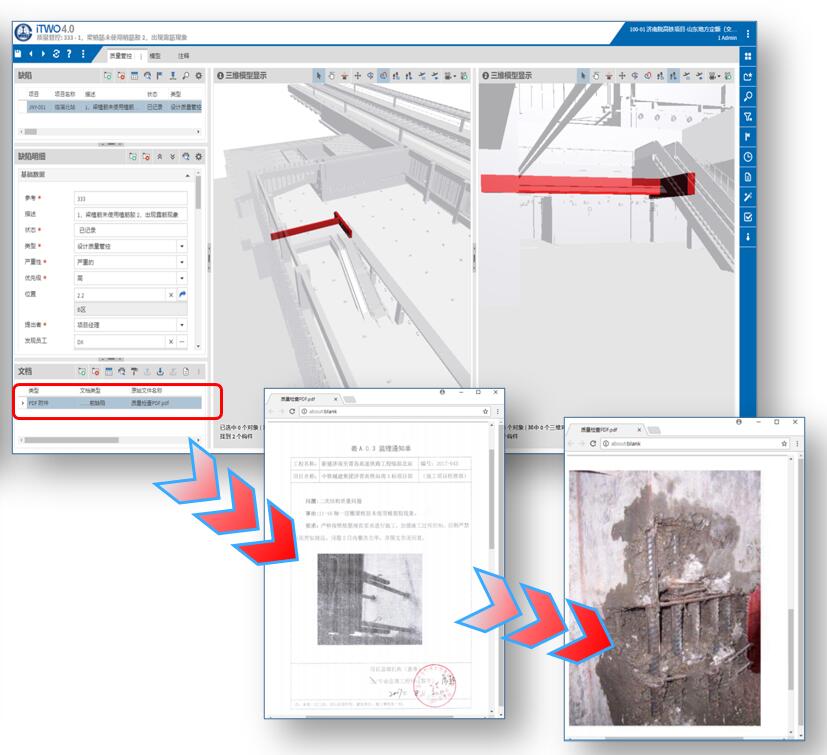

4. Quality management

With the RIB 4.0 mobile app, site teams were able to review the BIM model in the field to assist quality management. It allows team members to upload comments and documents such as photos, videos, and forms, so that all defect and safety issues are visual and easily accessible. This way, the CEC team can assign the respective staff timely to track and correct the defects and to further leverage quality control. Teams work in context and make informed decisions based on data, not guesses.

5. Change management

Change orders during construction can lead to an increase in investment and delays in progress. With RIB 4.0, the CEC team was able to upload changed models to quickly locate the changed components and generate the according bill of quantities for appropriate scheduling and resource adjustment. By sharing the BIM model, teams quickly realized effective management and dynamic control of design changes.

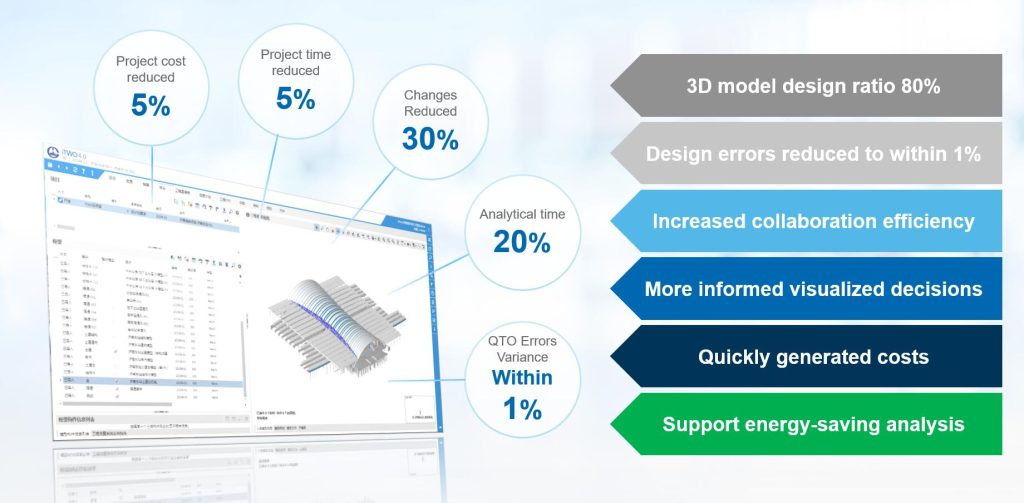

The Outcome

With the cloud-based enterprise RIB 4.0 platform, different stakeholders involved in the same project were able to collaborate based on the BIM model in one place.

Benefits achieved with RIB 4.0

- Reduced 5% of the project cost

- Reduced 5% of the project time

- Reduced 30% of changes

- Saved 20% of analytical time

- Quantity takeoff errors were controlled within a variance of 1%

The first RIB 4.0 textbook in the Chinese market

Based on their hands-on experience in project implementation with RIB 4.0 and entrusted by the Ministry of Industry and Information Technology and the Career Appraisal Center of the Ministry of Human Resources and Social Security, and with the support from the RIB team, China Railway Engineering Consulting Group published the first Chinese RIB 4.0 textbook “Collaboration Platform for BIM Application – Mastering RIB 4.0” in May 2019.

“We have been exploring the application of engineering projects on the RIB 4.0 platform since 2018 and we can feel the power of the RIB 4.0 platform in terms of collaboration, functionality, and user experience.”

— Wang Xiaogang

General Manager, Jinan Informationization Center

China Railway Engineering Design & Consulting Group., Ltd

At RIB 4.0 Construction Cloud, we are committed to keeping your teams, data, and processes connected. Learn more about how RIB 4.0 can help with your enterprise projects today! Download the Future-Proof Your Construction Business whitepaper below or sign up for a live demo with our product experts and see how RIB 4.0 can help your team build better, faster, and smarter.

Most Recent

22 mins read

15 mins read

49 mins read

24 mins read

E-BOOK